ETS TECH NEWS

By Scott Harrison, RCDD

Alamon is embracing the future by using technology to our advantage. Leveraging the skills and equipment we have in-house, we are able to improve the quality of our installations and save time and money.

Alamon is embracing the future by using technology to our advantage. Leveraging the skills and equipment we have in-house, we are able to improve the quality of our installations and save time and money.

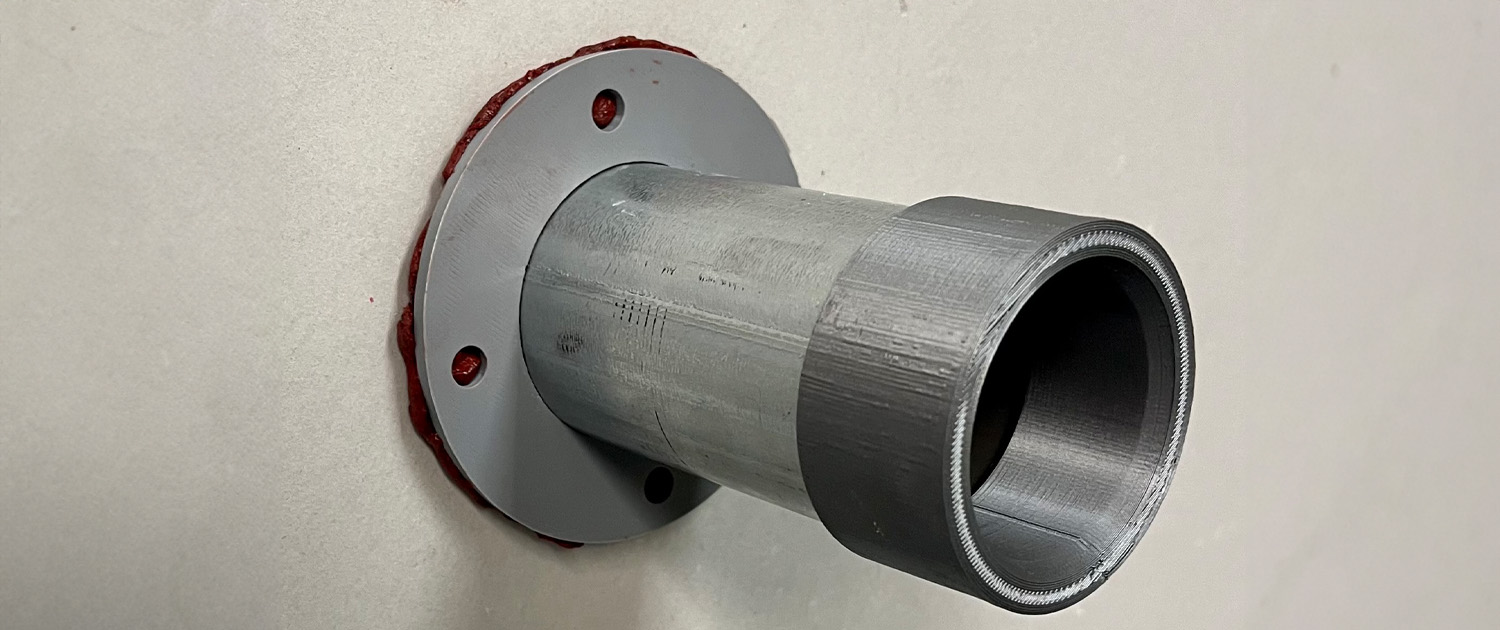

A recent example is at the Veterans Hospital in Reno NV where Alamon is upgrading the communications infrastructure system throughout the facility as a part of the Electronic Health Records Management initiative. This is a decently large medical campus with multiple old buildings, which present challenges when it comes to running the 6,000+ Category 6A cables that we are installing as a part of the project. In particular, overhead passage through firewall typically requires us to cut our own access holes and install a firewall sleeve to meet NEC code and the government specified standards. The typical solution would be to utilize a product like an EZ-Path sleeve.

The Challenge

While it certainly meets the requirements, the EZ-Path sleeve also poses a couple of problems, notably the expense of buying them and the time it takes to install them. Cutting a square hole through a lath and plaster wall overhead in a ceiling requires a vibratory saw, careful measurements on both sides of the wall as the square holes need to be aligned pretty closely for the sleeve to go through the wall properly and then you have to fire caulk it afterwards. Each one takes the better part of 30 minutes (actual average time is around 25 minutes) to install and each sleeve costs approximately $120. Over the course of this job, we could easily use 200 or more sleeves, adding up to a project expense of more than $20,000 for the sleeves. Fortunately, we found a better way to solve this problem.

THE PROJECT: Upgrading the communications infrastructure system at VA Sierra Nevada Health Care System in Reno, Nevada.

The Solution

ETS 3D Printer

Alamon purchased its own 3-D printer earlier this year and has put it into production printing consumable products such as conduit sleeve caps and ty-wrap cleats at a considerable savings over purchasing them through distribution or worse yet, sending someone to Home Depot to buy them.

Our resident engineering guru James Presnell has designed several unique prototypes that we look to move into production shortly, such as a Resi-Drill holster for UTVs that will save wear and tear on these expensive tools (not to mention repair costs and downtime).

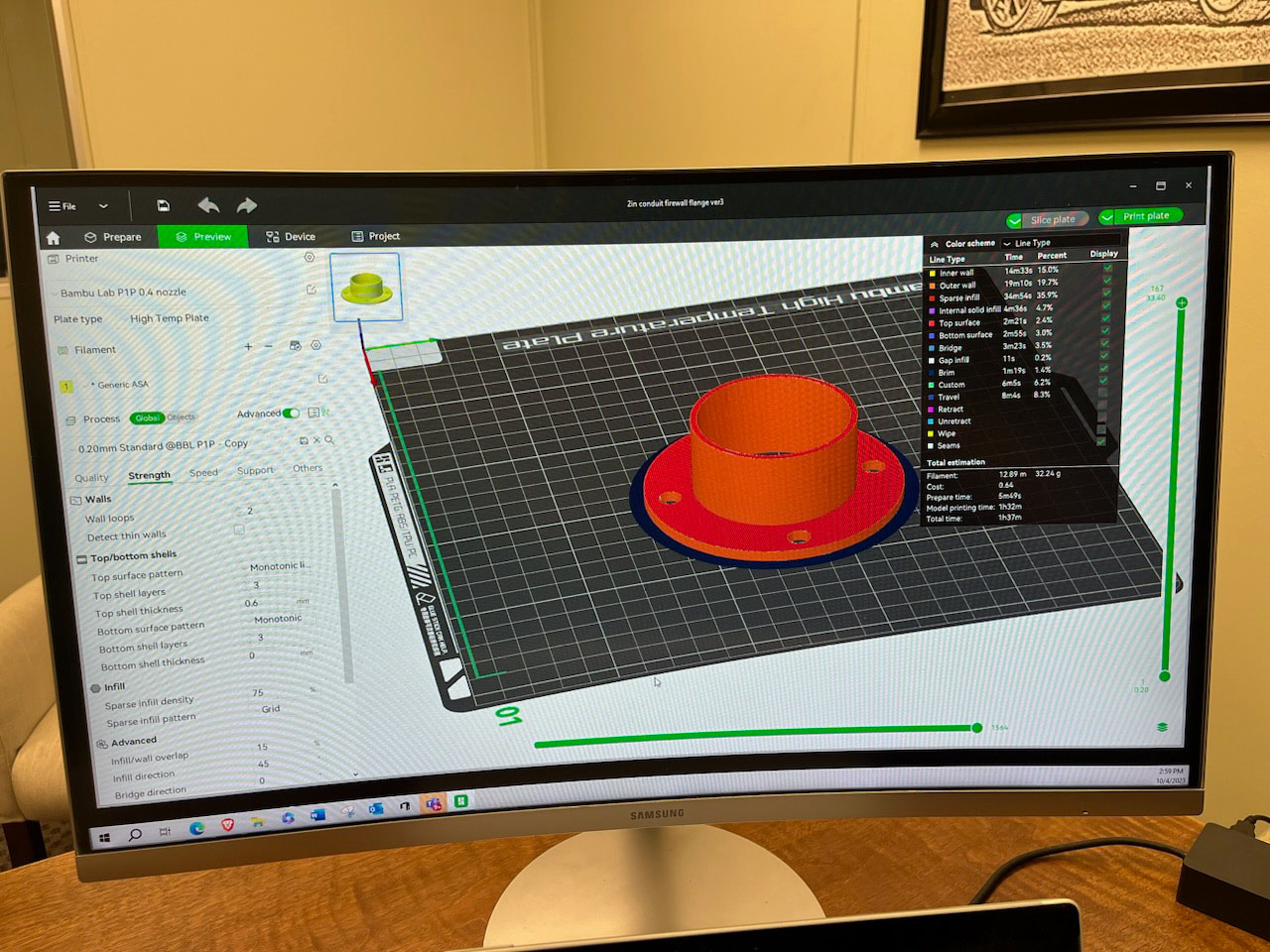

We decided that replicating our own custom design for a conduit flange would be another viable use of this technology, so we got to work.

The printing process itself is an “additive” process where a plastic filament is heated to the point that it will flow out an extrusion head that is mounted to a three-axis frame and the computer sends instructions to move it precisely according to the drawing’s coordinates, a layer at a time, starting from the bottom and constructing itself upwards until its finished. This product takes about three hours to print and costs about $0.83 in material. There is no comparable product available for purchase. The materials themselves are available in a wide variety of composites, including fire-rated filament that would be acceptable for an above ceiling environment.

The printing process itself is an “additive” process where a plastic filament is heated to the point that it will flow out an extrusion head that is mounted to a three-axis frame and the computer sends instructions to move it precisely according to the drawing’s coordinates, a layer at a time, starting from the bottom and constructing itself upwards until its finished. This product takes about three hours to print and costs about $0.83 in material. There is no comparable product available for purchase. The materials themselves are available in a wide variety of composites, including fire-rated filament that would be acceptable for an above ceiling environment.